Dimensional inspection is essential for ensuring the safety and reliability of critical infrastructure. By measuring the dimensions of a part, you can ensure that it meets the required specifications and is safe to use. Dimensional inspection can also help to identify defects in parts early on, preventing them from causing costly problems down the road.

Benefits of Dimensional Inspection

- Reducing production errors: Dimensional inspection ensures that the dimensions of the product meet the requirements of the specification, reducing the possibility of production errors and defects.

- Improving product quality: By inspecting the dimensions of the product, manufacturers can identify any deviations and correct them before the product is shipped, ensuring a higher quality product.

- Reducing warranty costs: By inspecting the dimensions of the product before it is shipped, manufacturers can identify potential issues and correct them before they occur, reducing warranty costs and customer complaints.

- Increasing customer satisfaction: By providing accurate and reliable dimensional inspection services, manufacturers can ensure that their products meet customer expectations and requirements, increasing customer satisfaction and loyalty

- Reducing rework and scrap: By accurately inspecting the dimensions of the product, manufacturers can avoid unnecessary rework and scrap, reducing production costs and increasing efficiency.

- Increasing production efficiency: Dimensional inspection can help manufacturers identify potential issues early in the production process, allowing them to take corrective actions quickly and efficiently, resulting in increased production efficiency and productivity.

Overall, dimensional inspection has numerous benefits for manufacturers, including reducing production errors, improving product quality, reducing warranty costs, increasing customer satisfaction, reducing rework and scrap, and increasing production efficiency. These benefits contribute to the success of manufacturers and their businesses.

Types of Dimensional Inspection

There are a variety of different dimensional inspection methods available, each with its own advantages and disadvantages. The best method for your application will depend on the specific part being inspected, the tolerances that need to be met, and the budget available.

Mechanical inspection

Mechanical inspection is the oldest and most basic type of dimensional inspection. It involves using a physical measuring tool, such as a micrometer or caliper, to measure the dimensions of a part. Mechanical inspection is simple and inexpensive, but it is also the least accurate type of dimensional inspection.

Optical inspection

Optical inspection uses a light source and a camera to measure the dimensions of a part. Optical inspection is more accurate than mechanical inspection, but it is also more expensive. Optical inspection is often used for parts with complex geometries or tight tolerances.

Laser scanning inspection

Laser scanning inspection uses a laser beam to scan the surface of a part. The laser beam is reflected off of the part and the reflected light is captured by a camera. The camera data is then used to create a 3D model of the part. Laser scanning inspection is the most accurate type of dimensional inspection, but it is also the most expensive. Laser scanning inspection is often used for parts with very tight tolerances or for parts that are difficult to measure with other methods.

Coordinate measuring machine (CMM) inspection

Coordinate measuring machine (CMM) inspection uses a CMM to measure the dimensions of a part. A CMM is a computer-controlled machine that uses a probe to measure the points on the surface of a part. The CMM data is then used to create a 3D model of the part. CMM inspection is very accurate and can be used for parts with very tight tolerances. However, CMM inspection is also very expensive. CMM inspection is often used for critical parts or for parts that are difficult to measure with other methods.

Computer-aided inspection (CAI)

Computer-aided inspection (CAI) uses software to automate the dimensional inspection process. CAI software can be used to create 3D models of parts, generate inspection plans, and analyze inspection data.

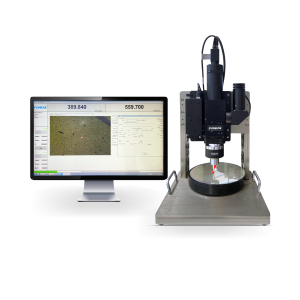

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com