With the development of science and technology, the requirements for manufacturing and processing are becoming more and more strict. Among them, automobiles are a means of transportation closely related to life, and their production and manufacturing requirements are more precise. Spark plugs are an important spare part in automobiles. And machining accuracy affects the performance of the car.

There are multiple sizes of spark plugs that need to be measured, and the detection accuracy is relatively high, and it needs to reach the micron level. The traditional spark plug detection is mainly carried out manually, with simple detection equipment. This detection method increases the huge labor cost and management cost to the factory, while the accuracy and standardization are difficult to guarantee, and the detection speed and detection accuracy are far from enough. fulfil requirements.

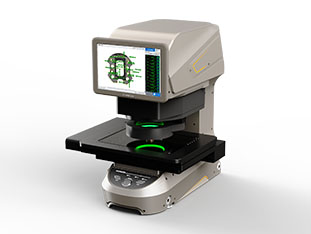

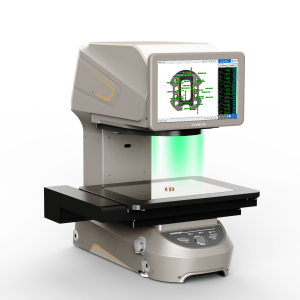

The Pomeas image size measuring instrument is equipped with a high-resolution bi-telecentric lens and a Gigabit network industrial camera, combined with an independently developed image processing system, using optical vision to obtain the image of the object to be measured, and using the image processing system to process the image. The measurement of the image of the object to be measured can achieve the measurement of the object, which can meet the requirements of spark plug size measurement. The Purmis image measuring instrument incorporates the principle of one-button flash measurement, and the measurement speed is fast. It can complete the measurement of 100 parts in 1 second, and has a large imaging range. It can be detected in batches. It is non-contact, fast, low cost, good stability, anti- It has outstanding advantages such as strong interference ability, improves production efficiency, shortens production cycle, and effectively solves a series of problems existing in traditional measurement methods.

At present, the main application field of machine vision is the field of industrial inspection, such as visual inspection of printed circuit boards, automatic flaw detection of steel plate surfaces, parallelism and perpendicularity measurement of large workpieces, automatic identification and classification of mechanical parts, and geometric dimension measurement. Pomeas image measuring instrument currently has a good performance in the detection of mobile phones, glass, PCB circuit boards, hardware, and small auto parts.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com