The light source is an important part of the machine vision system. Its function is not only limited to highlight the detection characteristics of the tested parts, but also can overcome the interference of ambient light, improve the signal-to-noise ratio of the image, and improve the positioning, measurement, and recognition accuracy of the vision system. The operating speed of the system and the reduction of the complexity of the system design.

The choice of light source is an important step in the construction of a vision system. Choosing a suitable light source can greatly reduce the difficulty of image processing and improve the stability and reliability of the system. Therefore, it is necessary to understand the classification and application of machine vision light sources.

Machine vision light sources can usually be divided into the following categories according to their shapes:

1. Bar light source

The strip light source is composed of high-density in-line LED arrays, the size design is flexible, the illumination angle can be adjusted according to the detection requirements, and the colors can be matched and combined freely according to the detection requirements. It is suitable for the detection of scratches and cracks on the surface of large-area objects.

2. Ring light source

The ring light source array is conical and irradiated on the surface of the measured object at an oblique angle, which can highlight the changes in the edge and height of the measured object. Applicable to product appearance packaging, label inspection; PCB substrate inspection; IC component inspection and other projects.

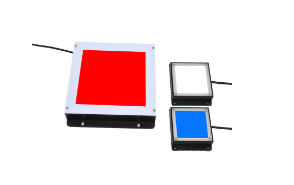

3. Surface light source

The surface light source is mainly used for coaxial backlight, and the surface light source is mostly used for coaxial backlight. It can be used for contour measurement, size detection, scratch detection on the surface of transparent objects, etc.

4. Dome light source

The lamp beads are generally installed at the bottom of the dome, and the target is indirectly illuminated through the diffuse reflector of the dome, and the dome light is mostly coaxial indirect light. It can be used for surface detection of reflective objects such as metal and glass surfaces; coding detection at the bottom of cans; appearance detection of food and medicine, etc.

5. Coaxial light source

The coaxial light source can eliminate the interference caused by uneven shadow images, so that the light source can evenly illuminate the surface of the object, which improves the accuracy and reproducibility of the machine vision system. It can be applied to scratch detection on highly reflective surfaces such as metal glass bottles; laser marking detection on wafers; character recognition detection on bearings and beverage cans.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0857

Fax:+ 86-0769-2266 0857 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com