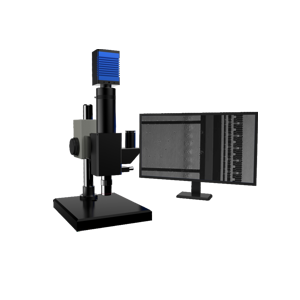

Ultra-Wide-Field Telecentric Measurement System | Precisely Captures Minor Wear on Metal Round Tubes

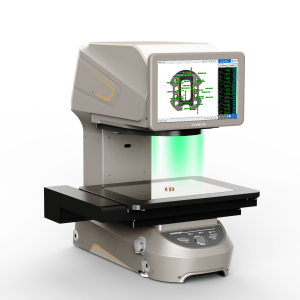

The HM-1120 telecentric measurement system with an ultra-wide field of view serves as the core inspection equipment, achieving 1.5μm precision to capture minute dimensional variations and ensure pr......

Application example of double telecentric lens: Watch inspection

The double telecentric lens effectively eliminates this interference, clearly revealing minor scratches, stains, and other imperfections on the glass surface, ensuring that every watch glass meets ......

Telecentric Measurement System for Terminal Wire Spacing Inspection

The HM Series Telecentric Measurement System uses machine vision technology to achieve non-contact, high-precision, high-speed detection of terminal wire spacing....

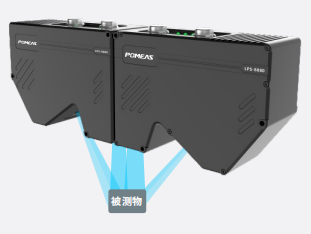

What are some typical applications of line laser profile sensors in industrial automation?

Line laser profile sensors have become a key technology in the field of industrial automation thanks to their high-precision 3D shape reconstruction capabilities and millisecond-level detection spe......

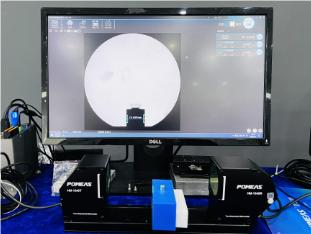

Line laser profile sensor: Meets the high-precision inspection requirements of the 3C industry

The non-contact scanning of the line laser profile sensor can accurately measure the flatness of the screen glass or assembly, ensuring display performance and touch sensitivity....

Laser contour scanning sensor: Precision part step measurement

The laser contour scanning sensor uses line laser projection technology to capture the deformed contours of the laser on the surface of the part through a high-speed CMOS camera. Combined with the ......

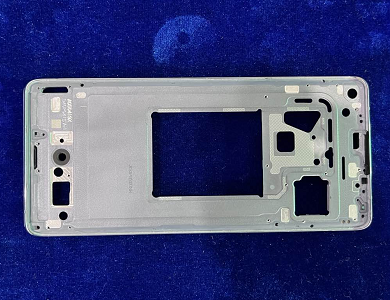

Is 6 million points sufficient for scanning the outline of a mobile phone frame?

Line laser profile sensors scan the middle frame of mobile phones and generate a 3D point cloud of 6 million points, which is a typical application of high-precision 3D measurement technology in co......

What is used to measure cylinders on the production line?

The Telecentric Measurement System is directly embedded at the end of the production line and uses non-contact measurement technology to perform efficient inspections without damaging the workpiece....

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION