The composition of the smart watch is the same as that of the smart phone. The screen components, the middle frame and the bottom cover are used as external parts. The flatness of the middle frame of the smart watch determines the placement position and available space of the internal electronic parts. If the temperature does not meet the requirements, the circuit board may warp, which will affect the heat dissipation and cause quality problems. In order to ensure the overall performance of the watch, the flatness of the middle frame needs to be tested.

Testing requirements:

Detect the dimensions such as the flatness of the outer contour of the middle frame of the watch and the difference in the hole position to determine whether it meets the quality control requirements.

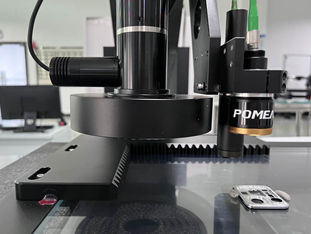

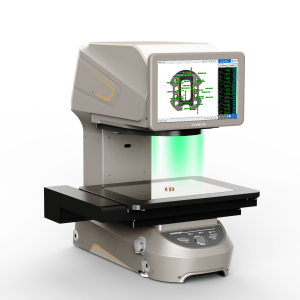

Detection scheme:

Using the POMEAS visual inspection solution combined with the point spectral confocal sensor, it can easily handle the size detection of the flatness and level difference of the middle frame of the watch. Require.

Program advantages:

1. Non-contact measurement, will not touch the surface of the workpiece, and will not cause wear on the product.

2. The measurement accuracy is high, up to μm level, which exceeds the traditional measurement tools, and can check the product quality very well.

3. The measurement efficiency is high, and multiple parameters such as flatness and level difference can be measured at the same time, which can be easily dealt with by random inspection or full inspection.

POMEAS is a core product supplier of machine vision and industrial automation, which can provide optical accessories and complete visual inspection solutions for industrial vision inspection customers.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com