Basic Components And Applications Of The Image Measuring Instrument

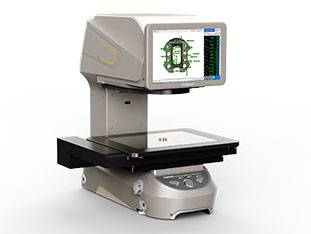

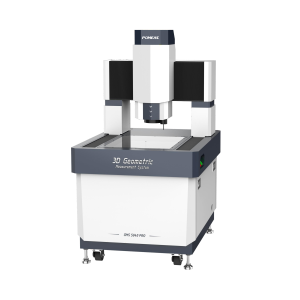

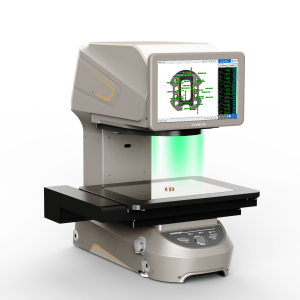

The Image Measuring Instrument is a high-precision measuring device mainly used to quickly and accurately measure objects of various shapes and sizes. It is characterised by high efficiency and accuracy and is widely used in manufacturing, inspection and maintenance. The following will introduce the basic composition of theImage Measuring Instrument structure and its scope of application to help better understand.

First, the basic composition of the Image Measuring Instrument

Image Measuring Instrument is mainly composed of the following parts:

1. Telecentric industrial lens: POMEAS IMAGE3 Image Measuring Instrument equipped with self-developed double-magnification dual-side telecentric lens, you can better capture the product outline, reduce the light source and camera requirements, while improving measurement accuracy.

2. Visual Light Source: The main role of the visual light source is to provide illumination so that the object being inspected can be clearly captured by the camera. The correct intensity of the light source enables optimum contrast and clarity of the image, resulting in a more accurate inspection system.

3. Industrial Camera: The POMEAS Image Measuring Instrument is equipped with a high resolution industrial camera, which is designed to receive image information from the telecentric lens and convert it into a digital signal. The high-resolution camera can better capture the details of the product contour and provide high-quality data for subsequent image processing.

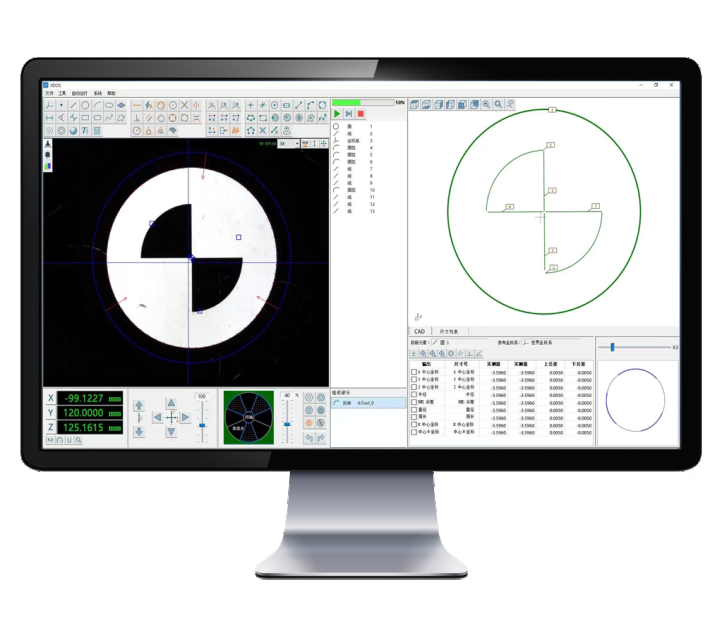

4. Image processing software system: image processing software can not only improve the speed of measurement, but also a variety of analyses and processing of images, while completing the evaluation of dimensional tolerances.

Second, the scope of application of the Image Measuring Instrument

Image Measuring Instrument has a wide range of applications, the following will introduce several major application areas:

1. Hardware field: Image Measuring Instrument can be used for rapid measurement of hardware parts, such as screws, nuts, rivets and so on. The size and shape of these parts is critical to the quality and performance of the product, the use of flash testers can quickly and accurately detect whether they meet the requirements.

2. Semiconductor field: Image Measuring Instrumentis also widely used in the semiconductor industry, such as in the chip packaging and testing stage. Flash testers can quickly and accurately measure the size and shape of chips to ensure that they meet design requirements and performance standards.

3. Mobile phone field: the manufacture of mobile phone parts requires high-precision measurement and detection. Image Measuring Instrument can be used for rapid measurement and detection of mobile phone parts, such as mobile phone screen, camera, keys and so on. Through the measurement of the Image Measuring Instrument it can ensure that the size and shape of each component meets the requirements, thus improving the quality and performance of mobile phones.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com